As the name bottom pressing suggests the punch presses the metal sheet onto the surface of the die so the die s angle determines the final angle of the workpiece.

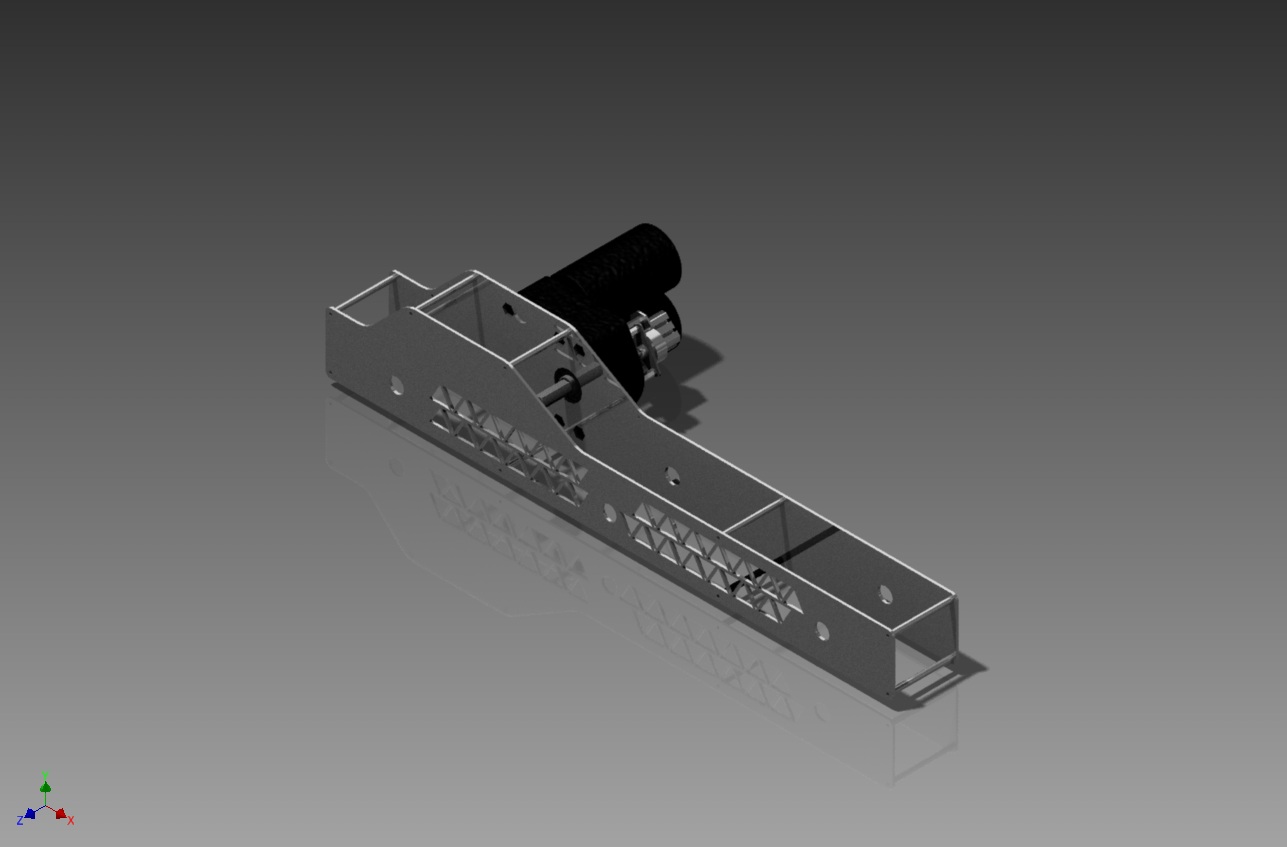

Punched bent sheet metal frc.

Bottoming is also known as bottom pressing or bottom striking.

Sheet metal should be bent at the minimum bend radius possible.

Item 168753 model 11786.

Does this mean that one size punch tip radius will work well with every application.

Another way of strengthening the sheet metal is by punching holes and slots.

As with any mechanical parts cutting and shaping process sheet metal punching can create sharp edges and burrs from time to time.

The punch tip radius usually has little influence.

Troy products is a subsidiary of troy sheet metal works inc.

In principle does not seem that this operation is complicated and difficult.

Hillman 12 in x 24 in cold rolled steel expanded sheet metal.

With a 25 000 square foot shop located in montebello ca troy sheet metal works services the industrial market nationwide.

When we air bend sheet metal the size of the die v opening determines the inside radius of the bend.

Perforated metal wall cladding fabricated perforated metal cylinder perforated metal cone strainer perforated metal airport screen marco can meet your perforated metal product needs as one of the top perforated steel sheet suppliers in the united states marco specialty steel can serve the needs of companies in a wide range of industries.

Using rotational dies the punch secures the perforated sheet as it initiates bending just as with tread plate.

Material bend radii and minimum bend size charts please note.

The bend radius you select may not be available if the geometry of the part will not allow us to bend with the specific tooling required to achieve that radius.

The bending of sheet metal with a punch and an array mounted at a folder is quite natural and normal.

The metal in the areas where holes and slots are punched gets stretched and become more tensile which gives more structural rigidity to the sheet metal.

Use the minimum bend dimension values in the charts below for your minimum closeness of cutout to a bend.

Metal of extremely high tensile strength may move regardless but in most situations as long as the clamping pressure is adequate to overcome the resistance your bend will be accurate wold said.

Troy products focuses on products geared toward public safety vehicles and similar apparatus.

Minimum punch radius 63 of the material thickness.